A Technical Guide for Fleet Managers and Heavy-Duty Vehicle Operators

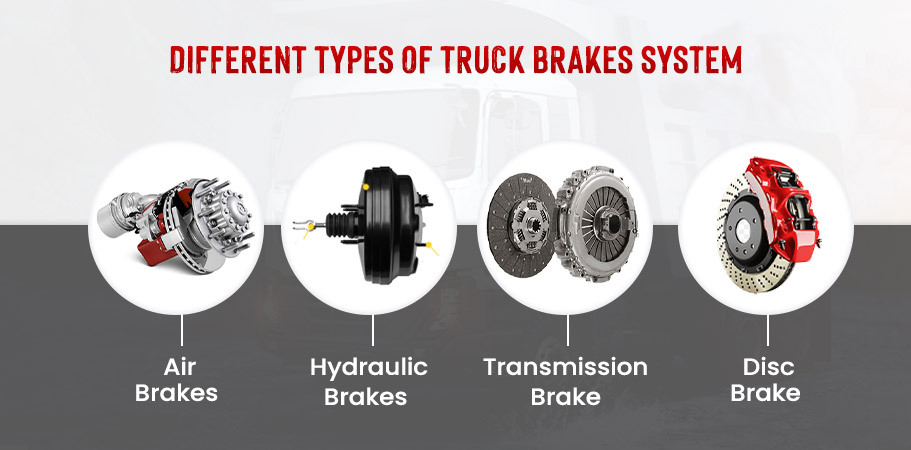

Truck braking systems are engineered to handle massive loads, steep gradients, and long-haul durability. Choosing the right system impacts safety, operating costs, and compliance. This guide explores 4 primary truck braking technologies, supported by real-world data, OEM applications, and OK PARTS solutions optimized for global markets.

1. Drum Brakes: The Workhorse of Heavy Hauling

Design & Functionality

Components: Brake shoes, drums, wheel cylinders, and S-cams.

Operation: Shoes press outward against the rotating drum, creating friction.

Key Metrics:

Lining Area: 1,200-1,800 cm² (Class 8 trucks).

Heat Dissipation: Limited; peak temps reach 600°C during prolonged braking.

Pros & Cons

| Advantages | Disadvantages |

|---|---|

| Lower upfront cost ($400/axle) | Overheating risks on long descents |

| Easier maintenance | 20-30% longer stopping distances vs. disc brakes |

| Proven durability in dry climates | Frequent shoe replacements (every 80,000-120,000 km) |

Real-World Applications

OEM Example: Freightliner Cascadia (rear axles).

OK PARTS Solution: OK-DB5000 Heavy-Duty Drum Brake Kit

Features: Manganese steel shoes, anti-fade linings.

Compliance: FMVSS 121, ECE R90.

Lifespan: 150,000 km in mining operations (validated by Australian fleet trials).

2. Disc Brakes: Precision Stopping Power

Design & Functionality

Components: Rotors, calipers, pads, and hydraulic/pneumatic actuators.

Operation: Calipers clamp pads onto rotors for linear friction.

Key Metrics:

Rotor Diameter: 430-510 mm (Class 8 trucks).

Cooling: Ventilated rotors reduce temps by 30% vs. solid designs.

Pros & Cons

| Advantages | Disadvantages |

|---|---|

| 15-25% shorter stopping distances | Higher cost (1,200−1,200−1,800/axle) |

| Better heat dissipation | Complex maintenance |

| Longer pad life (120,000-180,000 km) | Sensitive to oil contamination |

Real-World Applications

OEM Example: Volvo FH16 with Knorr-Bremse Disc Brakes.

OK PARTS Solution: OK-DB8000 Air Disc Brake System

Features: Slotted rotors, automatic adjusters.

Performance: 38-meter stopping distance at 60 km/h (25% better than drum brakes).

Certifications: ISO 7622, JIS D4411.

3. Engine Brakes (Jake Brakes): Deceleration Without Wear

Design & Functionality

Principle: Releases compressed air in cylinders to counteract engine rotation.

Types: Compression release (Jacobs), exhaust pressure (PACCAR).

Key Metrics:

Retarding Power: 300-600 hp equivalent.

Fuel Savings: 5-8% on mountain routes (reduced friction brake use).

Pros & Cons

| Advantages | Disadvantages |

|---|---|

| Zero brake wear | Loud operation (banned in some residential areas) |

| Continuous descent control | High installation cost (3,000−3,000−5,000) |

| Compatible with all brake types | Requires ECU integration |

Real-World Applications

OEM Example: Detroit Diesel DD15 with Jacobs Engine Brake.

OK PARTS Solution: OK-JB3 Retrofit Kit for Cummins ISX engines.

Deceleration: 0.4 m/s² at 2,000 RPM.

Noise Reduction: 5 dB quieter than Gen 2 Jake brakes.

4. Exhaust Brakes: Simple and Cost-Effective

Design & Functionality

Components: Butterfly valve in exhaust pipe.

Operation: Restricts exhaust flow, increasing backpressure.

Key Metrics:

Retarding Force: 20-30% of engine brake capacity.

Cost: 500−500−800 (aftermarket installation).

Pros & Cons

| Advantages | Disadvantages |

|---|---|

| Affordable auxiliary braking | Limited effectiveness above 2,500 RPM |

| Silent operation | Does NOT replace service brakes |

| Easy installation | Minimal impact on steep grades |

Real-World Applications

OEM Example: Hino 300 Series (integrated exhaust brake).

OK PARTS Solution: OK-EB200 Universal Exhaust Brake

Compatibility: Fits 3-6L diesel engines.

Durability: 304 stainless steel valve (200,000+ cycles tested).

5. Hybrid Braking Systems

Combining Technologies for Optimal Performance

Example: WABCO OptiDrive™ (Disc brakes + predictive engine braking).

Function: Uses GPS and terrain data to pre-activate engine brakes.

Results: 12% lower pad wear, 7% fuel savings (Daimler field tests).

OK PARTS Innovation: OK-Hybrid+ System

Integration: Air disc brakes + exhaust brake + telematics.

Ideal For: Refrigerated trailers and LNG tankers.

6. Choosing the Right System: Decision Matrix

| Factor | Drum Brakes | Disc Brakes | Engine Brakes | Exhaust Brakes |

|---|---|---|---|---|

| Initial Cost | $400/axle | $1,500/axle | $3,000+ | $800 |

| Maintenance Cost | $0.08/km | $0.12/km | $0.03/km | $0.01/km |

| Mountain Performance | Poor | Excellent | Excellent | Fair |

| Best For | Dry climates, short hauls | High-value cargo, long descents | Logging, mining | Light-duty, urban |

7. Maintenance Tips for Longevity

Drum Brakes: Inspect S-cam bushings every 60,000 km; replace if wear exceeds 1.5 mm.

Disc Brakes: Check rotor thickness monthly; minimum operational thickness is 38 mm for Class 8 trucks.

Engine Brakes: Flush engine oil every 300 hours to prevent valve clogging.

Exhaust Brakes: Clean butterfly valve every 50,000 km to prevent carbon buildup.

8. Industry Trends & Innovations

Electro-Mechanical Brakes (EMB): Fully electric systems (tested by ZF for autonomous trucks).

Regenerative Braking: Scania’s hybrid trucks recover 15 kWh energy per descent.

OK PARTS R&D: SmartBrake AI™ predictive maintenance system (launching Q3 2024).

Why Partner with OK PARTS?

Global Reach: 98% same-day shipping coverage across Europe, North America, and APAC.

Certifications: ISO 9001, IATF 16949, and CCC (China Compulsory Certification).

Custom Solutions: Brake kits tailored for Mercedes Actros, Kenworth T680, and emerging EV trucks.

Final Insights

From drum brakes’ cost efficiency to disc brakes’ precision stopping, each system serves unique operational needs. Fleet managers must weigh total cost of ownership, terrain challenges, and regulatory demands. With OK PARTS’ engineered solutions, operators achieve safer, more profitable hauls—whether navigating Swiss Alps passes or Australian outbacks.